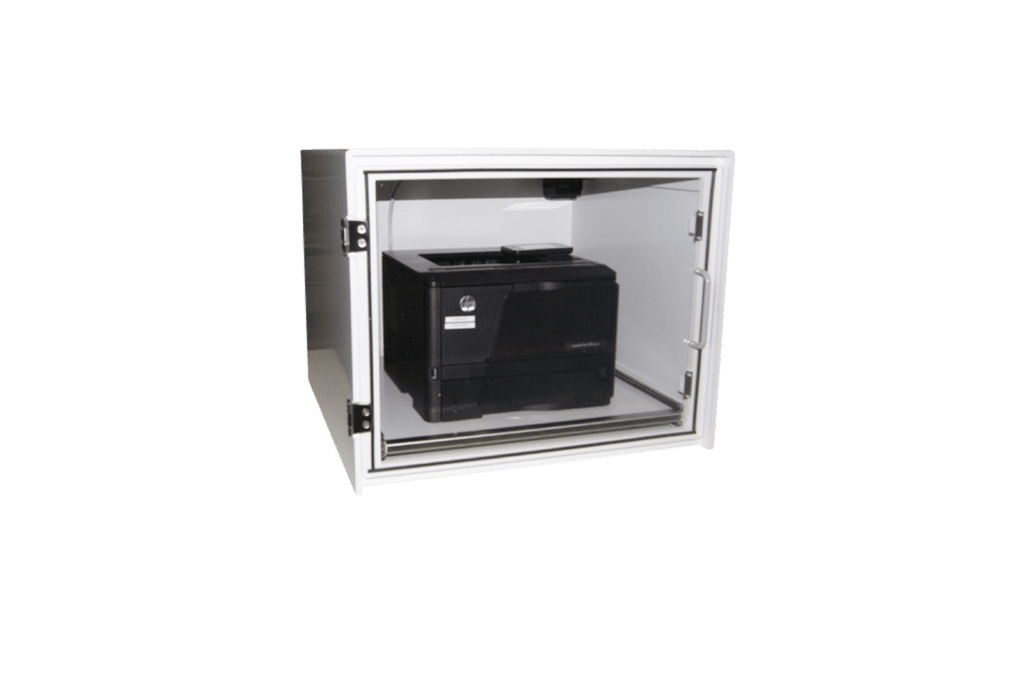

In the industrial sector, the protection of IT equipment is essential. THE waterproof industrial computer cases offer a robust solution to ensure the safety and durability of workstations in harsh environments. This article explores this crucial topic in depth, covering their features, benefits, and practical applications.

Why use a waterproof industrial computer case?

THE industrial environments can be particularly hostile to computer equipment. There dust, water, vibrations and extreme temperatures are all factors that can harm the proper functioning of industrial PCs. This is where waterproof computer cases come into play.

Protection against water and dust

A waterproof computer case provides an effective barrier against water and dust. These particles can in fact damage the internal components of a computer or screen, making their use unreliable in the long term. Boxes are often classified according to protection indices (IP) to determine their resistance to external elements.

- IP65: Total protection against dust and water jets from all directions

- IP66: Total protection against dust and powerful water jet

- IP67: Temporary immersion in water

Resistance to shock and vibration

Industrial environments are not just limited to surface contamination. They often involve heavy machinery producing constant vibration. Rugged computer enclosures are built to withstand these conditions, protecting internal systems from potential damage.

Thermal control

Maintaining an optimal temperature inside the enclosure is essential for the proper functioning of electronic devices. Some models include specific compartments to improve air circulation or integrate active cooling systems such as fans. Others use materials with high thermal conductivity to dissipate heat efficiently. Applications of sealed industrial computer enclosures

The use of enclosures is not limited to a specific sector; they find their place wherever environmental conditions require enhanced protection of electronic devices.

Manufacturing industry

In manufacturing, workshops are home to a multitude of polluting and heat-generating processes. Screens and central units therefore require robust enclosures to maintain their functional integrity and extend their lifespan. Here are some commonly performed tasks:

Production process monitoring

- Automated quality control

- Real-time logistics tracking and inventory management

- Food industry

Food processing requires strict hygienic standards that include the use of

stainless materials and easy-to-clean sealed cabinets . Equipment protected by sealed cabinets makes it easier to meet these standards without sacrificing technological functionality.Pharmaceutical industry

Pharmaceutical laboratories and production facilities require ultra-clean environments. The integration of computer cabinets maintains a high level of cleanliness while ensuring maximum protection of equipment used for monitoring and controlling drug formulations.

Important features to consider when purchasing

The choice of a computer box must be based on several criteria to ensure that it perfectly meets the specific needs of your industry.

Size and Compatibility

The size of the box should match the dimensions of your devices to increase ease of installation and avoid any internal movement that could cause damage.

Internal dimensions adjusted to screens and CPU

- Compartmentalization possibilities for different equipment

- Building material

Different materials provide varying levels of protection. L’

stainless steel, for example, is ideal for environments requiring high corrosion resistance, such as the food industry and chemical production.Locking systems and security

Besides the

environmental protection , securing against unauthorized access is crucial. Of theheavy duty locks and anti-tamper mechanisms can add an extra level of security to your IT installations. Ease of access and maintenance

Although protection is essential,

ease of access for maintenance provides a significant time saving. Look for removable panel options or doors that allow quick access to repair or update equipment without too much complexity. Cost and return on investment

Investing in an industrial computer box may seem expensive initially, but the

return on investment quickly manifests itself in reduced downtime and increased device lifespan. Take the time to compare the different options available to balance cost and performance. Comparison between different types of boxes

There are several types of computer cases on the market, each meeting specific needs. Below is a brief comparison to help you guide your choice.

Wall box vs. autonomous box

THE

wall boxes save floor space and are ideal for environments where space is limited. On the other hand, the autonomous boxes , often mounted on feet, can be easily moved if necessary.Housing with passive cooling vs. active

The choice between a system of

passive cooling (using heat sinks) and a active cooling (including fans) depends on the amount of heat generated by the contained devices. Active cooling is best suited for high-performance setups requiring precise temperature control. Standard box vs. custom made

THE

standard boxes are designed for common and immediate uses, while the custom boxes are specifically tailored to unique needs. Companies with very specific protection specifications will benefit from opting for personalized solutions. Installation and maintenance of computer boxes

To maximize the benefits of your investment, correct installation and regular maintenance of your boxes are essential.

Initial installation

During installation it is necessary to ensure that all electrical and network connections are correctly aligned and protected. Professionally supervised commissioning also ensures that all

security settings are configured according to industry standards. Preventative maintenance

Plan

regular inspections to check the physical integrity of the box as well as the performance of the cooling systems and seals. Rigorous maintenance prevents unexpected breakdowns and ensures continued operational efficiency. Future and innovations in industrial computer boxes

With the constant progress of technologies,

innovations in the field of industrial housings are continually evolving to meet the growing challenges of modern industry. IoT integration

Advanced connectivity with

internet of things (IoT)now makes it possible to monitor in real time the internal conditions of the boxes such as temperature, humidity and vibrations. This proactive monitoring helps anticipate and prevent failures before they impact productivity. Advanced materials

New discoveries in the field of materials, notably

high performance polymers and light alloys, further increase the resistance of the boxes while reducing their weight. These advances offer new application possibilities and broaden the horizons of protection.